↵

Some Statistics About Us You Must Know

Choose the plan that suits you best.

18

+

YEARS OF EXPERIENCE

3000㎡+

FLOOR SPACE

160

+

MACHINERY EQUIPMENT

3500

+

SATISFIED CUSTOMERS

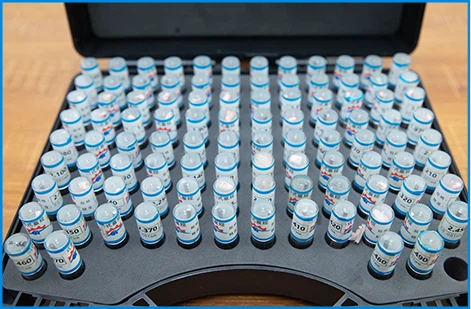

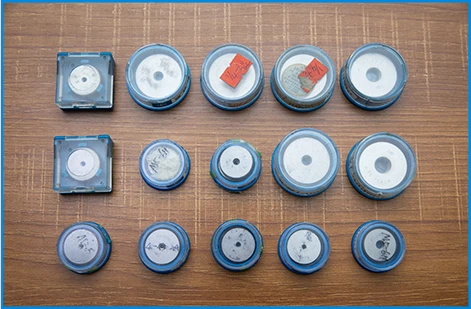

Product Picture

Plastic transparent clear PC screw

PC Screws, also known as acrylic screws or organic glass screws.

Heat Resistance Temperature: 115°C

Flammability: UL94 V-2

Features: Insulation, dry resistance. Transparent screws allow light transmission and exhibit excellent aging resistance and oxidation resistance. The surface hardness is high, making them resistant to scratches. They possess exceptional impact resistance, remaining deformation-free even when dropped or struck, and offer good mechanical performance. The lightweight design also helps reduce the load on equipment. Compared to common nylon screws, PC nylon screws have higher transparency and a longer lifespan, but their UV resistance is relatively weaker.

Applications: Microelectronics, exterior components

Examples of Polycarbonate Screw Usage:

Application : Chassis, microelectronic devices

Purpose: Insulation, lightweight

Shape: Pan head small screws

Size: M1.7–M4

Application: Decoration, exterior components, automotive and motorcycle parts

Purpose: Impact resistance

Shape: Pan head small screws

Size: M3–M6

Application: Decoration, exterior components, toys

Purpose: Aesthetic design

Shape: Pan head small screws

Size: M3–M6

Advantage and disadvantange of Nylon screw

Advantages

1.Compared to ordinary metal screws, the greatest advantage of nylon screws is their excellent insulation properties, as they do not conduct electricity.

2.Additionally, because they are made of non-metallic materials, they do not generate eddy currents or other signal interference under the influence of electric currents or other electrical signals. This anti-interference characteristic makes them suitable for industries such as telecommunications.

3.Nylon screws exhibit good resistance to acids and alkalis. Among them, PVDF screws perform the best, followed by polypropylene (PP) screws. Both have strong acid and alkali resistance, whereas ordinary plastic screws are inferior to the two in resisting strong acids and alkalis. Therefore, nylon screws, especially PVDF screws, are widely used in industries like electroplating, where strong acidic or alkaline environments are common.

Disadvantages

1. The biggest drawback of nylon screws is that their torque and strength are generally inferior to those of ordinary metal screws. Excessive torque may lead to thread stripping or head breakage.

2.Due to factors such as shrinkage during plastic molding, temperature and humidity variations, and differences in molding cycles, nylon screws tend to have larger dimensional tolerances. Moreover, because ordinary nylon is relatively soft, conventional ring gauge measurement methods cannot be used.

Nylon has a strong tendency to absorb water. Under different temperatures and humidity levels, nylon products will absorb water until they reach a certain proportion, known as the "equilibrium point." The equilibrium point of water absorption varies depending on the surrounding environment (temperature, humidity, etc.).

The rate of water absorption in nylon also depends on the thickness of the product. Controlling the amount of water absorption is crucial for the practical application of nylon products. The degree of water absorption significantly impacts the performance of nylon products: freshly manufactured products are typically stiff, brittle, and lack elasticity, making them prone to breakage. To achieve higher tensile strength, the water absorption proportion should be lower; to achieve better toughness, the water absorption proportion should be higher.

How water absorption affects the performance of nylon products:

Higher water absorption improves endurance (fatigue resistance), toughness, and elongation. However, it also reduces tensile strength, electrical insulation, and dimensional stability.

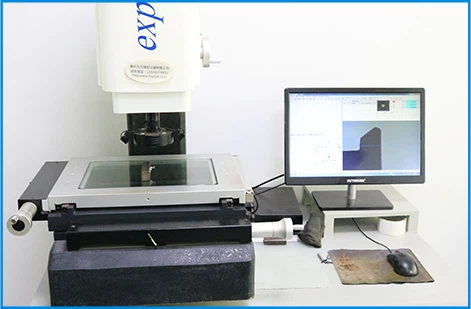

Production Process

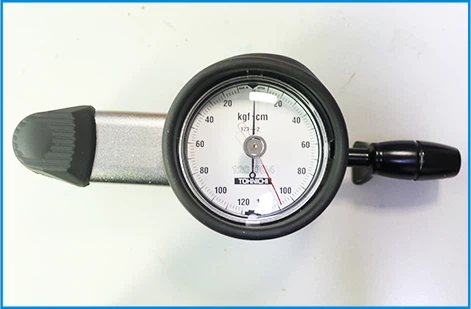

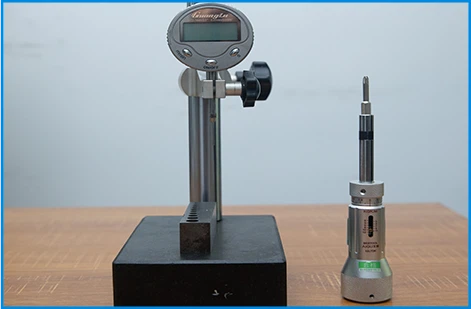

Quality Control

FAQ

Q1: Can you provide custom Plastic transparent clear PC screw?

A1: It can be made according to the drawings and specifications provided by customers.

Q2:Do you offer samples for free?

A2: For standard ones, we can send samples for free, and you pay the shipping fee.

Q3: Is other material available for plastic screws

A3: Yes, material such as nylon. PEEK.

Q4: What's the lead time to produce the plastic PC screw

A4: Lead time will much depend on the design. Standard is 15-18 days.

Please contact us if you have need for the transparent PC screws at email sales@hky-hardware.com

Hot Tags: plastic transparent clear pc screw, China plastic transparent clear pc screw manufacturers, suppliers, factory