↵

company Product Scale

Choose the plan that suits you best.

18

+

YEARS OF EXPERIENCE

3000㎡+

FLOOR SPACE

160

+

MACHINERY EQUIPMENT

3500

+

SATISFIED CUSTOMERS

Carbon steel hexagon socket tapping screws (carbon steel tapping screws) are fasteners designed for connecting speakers, audio equipment, thin sheet metal and wooden structures. The product is made of 1022 carbon steel and manufactured through an 8.8-grade high-strength cold heading process. The surface is treated with black oxide, which has both rust resistance and industrial aesthetics.

The unique arc-shaped triangular thread section design, combined with a sharp tail end, achieves low screw-in torque and high locking performance. It can be directly installed without pre-drilling in scenes such as 0.5-6 mm-thick color steel plates, wooden speaker panels, and metal brackets.

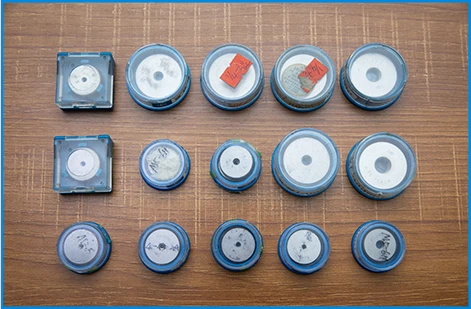

Product Picture

Core product features

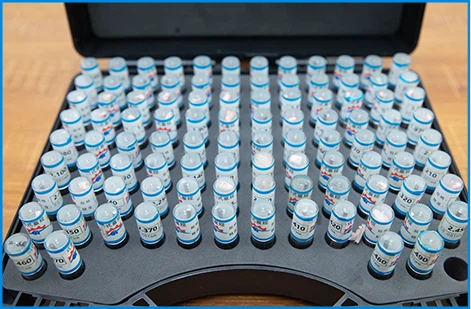

High strength and durability: 8.8-grade hardness standard, the thread surface is strengthened to ensure the connection stability of audio equipment in a vibrating environment, the black surface is treated with anti-rust, the black oxide coating provides corrosion protection, and the salt spray test is greater than 480 hours, which is suitable for use in humid environments.

Precision engineering structure: The integrated design of self-drilling and self-tapping realizes the simultaneous completion from drilling to tapping to the final locking. Shorten the product installation time. The cylindrical head hexagonal design can withstand 200% more torque than cross-slot or slotted screws, and is suitable for high-frequency installation scenarios.

Production Process

Industry adaptation: thin plate penetration experts, optimize thread depth and pitch to avoid thread slippage.

Customized services provided

Material upgrade: Carbon steel self-tapping screws provide stainless steel A2-304 and A4-316 material options to enhance the product's corrosion resistance and are suitable for marine climates or outdoor audio equipment. You can choose color zinc plating or white zinc plating, as well as Dacromet coating and phosphating treatment.

Structural customization: Flange gasket integrated design, integrated rubber gasket, to achieve waterproof sealing, suitable for outdoor speaker equipment.

Industry application scenarios

Audio equipment manufacturing: speaker unit fixing and speaker box assembly

Architecture and furniture: color steel plate connection, display rack, or metal furniture

Automobile and electronics: car audio bracket, control cabinet sheet metal

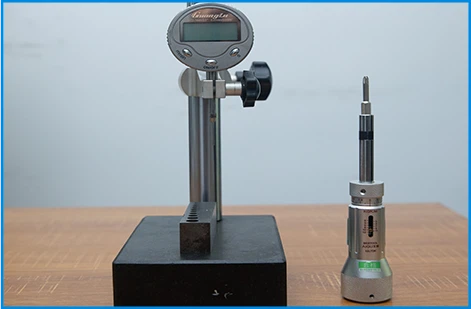

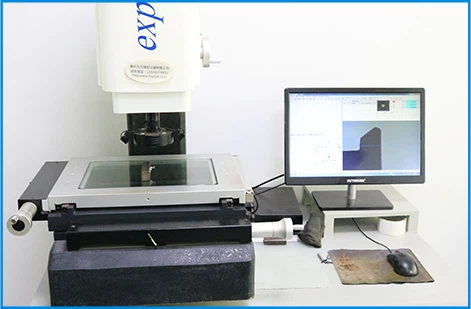

Quality Control

Why choose us?

Through product life cycle quality management, we ensure that every link from raw material procurement to finished product delivery meets the most stringent industrial standards, providing reliable fastening solutions for your critical equipment. We will continue to be committed to providing the most reliable fastening solutions to customers around the world. Whether you need standard specifications of carbon steel self-tapping screws or face special application challenges, our engineering team can provide professional support.

Hot Products

Hot Tags: carbon steel self tapping screws, China carbon steel self tapping screws manufacturers, suppliers, factory, screw, Strip Resistant Screws for Sheet Metal, tapping screw, Tapping Screws for Wood, Thread Cutting Screw for Metal, Thread Forming Screws for Soft Metal