↵

Company Product Scale

Choose the plan that suits you best.

18

+

YEARS OF EXPERIENCE

3000㎡+

FLOOR SPACE

160

+

MACHINERY EQUIPMENT

3500

+

SATISFIED CUSTOMERS

Non-standard stainless steel C-head cross M2 M3 M4 slotted step screws radiator screws (radiator screws) are customized fasteners specially used for electronic radiator assembly. Our company specializes in the production of non-standard stainless steel radiator screws, mainly cross slot countersunk step screws series products. These precision fasteners are made of high-quality 304 stainless steel, with the characteristics of corrosion resistance, high strength, and precision tolerance, and are designed and developed to meet the stringent requirements of various radiator assembly scenarios. Our products are widely used in CPU radiators, power electronic equipment cooling modules, industrial inverter cooling systems, and new energy vehicle cooling devices. The common pain points of traditional screws in radiator installation, such as protruding heads, loose thread bites, and thermal stress fractures.

In response to the special needs of the radiator industry, we provide high-precision products with a length tolerance of ±0.05mm to ensure stable operation on automated assembly lines. The product is compatible with various radiator screw column structures, and can provide reliable fixing effects even for thin radiators, avoiding the risk of screws being too long and penetrating the cooling fins.

Our radiator screws integrate material science, precision manufacturing and application engineering to provide reliable connection guarantee for heat dissipation solutions

Advantages of stainless steel

304 stainless steel can provide excellent corrosion resistance and pass the 48-96 hours neutral salt spray test, which is suitable for electronic equipment in high humidity environments. Its tensile strength reaches 700MPa, and its yield strength is 450MPa, ensuring that the preload can be maintained under the heat cycle conditions of the radiator.

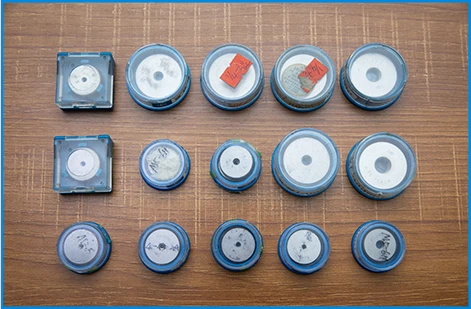

Product Picture

410 martensitic stainless steel: For application scenarios that require higher hardness and strength, the hardness can reach HRC 32-40 after heat treatment, and the tensile strength is increased to more than 850MPa, which is particularly suitable for vibration environments such as new energy vehicle drive unit radiator fixation.

Material traceability: All raw materials are provided with original material certificates, and support SGS third-party testing to ensure that the composition meets AISI standards.

Precision processing technology

Cold heading forming technology: Using Taiwan's precision cold heading machine for one-time forming, the product has higher metal streamline integrity and is about 20% stronger than turned parts.

Precise control of step thread: The precise transition between the thread and the polished rod is achieved through the segmented thread rolling process. The step diameter tolerance is controlled at ±0.03mm and the length tolerance is ±0.05mm, ensuring the clearance fit accuracy of 37 with the radiator screw column.

Cross slot optimization: The slot depth and angle are strictly processed according to the standard, and the slot depth consistency reaches ±0.02mm, which avoids the phenomenon of the screwdriver jumping during assembly and improves the efficiency of automated assembly.

Production Process

Radiator-specific design

Anti-penetration structure: By accurately controlling the thread length, ensure that the protrusion after installation is controlled within a safe range to avoid penetrating the cooling fins.

Thermal expansion compensation: The thread design takes into account the difference in thermal expansion coefficient between the radiator material and stainless steel, and provides customized pitch options to prevent loosening or stress cracking caused by thermal cycles.

Compatibility optimization: The step diameter is optimized for the inner diameter of the mainstream radiator screw column, which ensures both positioning accuracy and smooth installation.

Customized service process

We provide professional non-standard screw customization services for radiator manufacturers, with a scientific and efficient process:

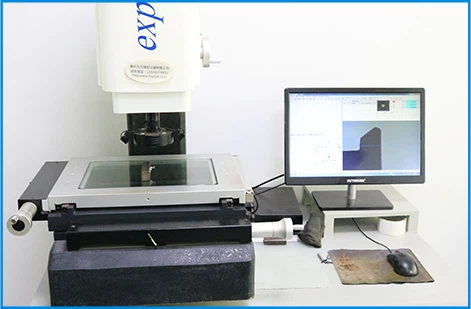

Quality Control

Requirements analysis stage:

Customers provide application scenario parameters: radiator types include push-down type and tower type, mounting plate thickness, screw column structure, special environment requirements, etc. Or directly provide CAD screw drawings, which need to mark thread specifications, step diameter and length, head form, material requirements, surface treatment, etc.

Technical evaluation and design:

Engineers recommend the best specifications based on the radiator structure (such as M3×16mm step screws are recommended for thin radiator IS-47XT; M3×32mm is recommended for T30 thick fans)

Provide anti-galvanic corrosion solutions for special materials, such as adding insulating coatings.

Sample production and verification:

Deliver the first sample within 3-5 working days (provide 5-20pcs test samples)

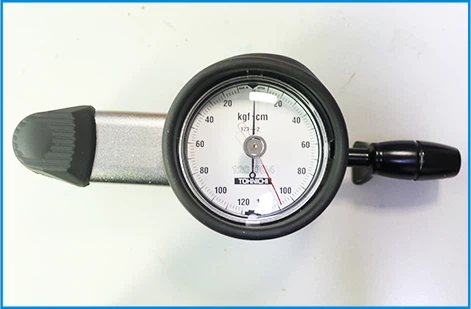

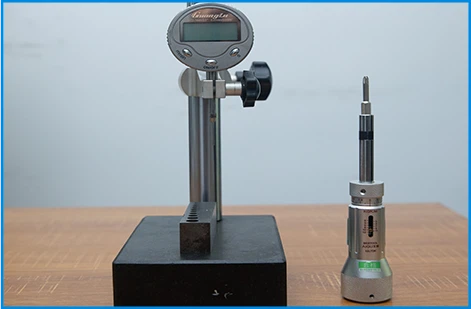

Support matching tests: including torque test, thermal cycle test, salt spray test, etc.

Batch production and quality control:

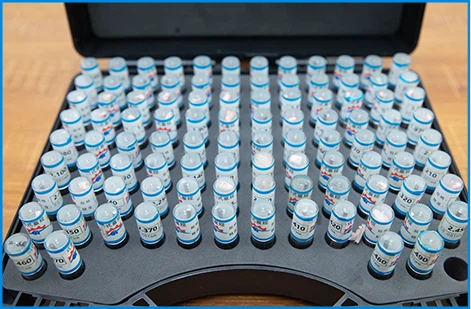

Use an automatic optical sorting machine for full-size inspection

Provide a material report and a salt spray test report for each batch

Special packaging can be provided according to customer requirements, PE anti-static bag + shockproof paper box, and label customization.

Hot Products

Why choose us?

Through the full life cycle quality management of radiator screw products, we ensure that every link from raw material procurement to finished product delivery meets the most stringent industrial standards, providing reliable solutions for your critical equipment. We will continue to be committed to providing the most reliable fastening solutions for customers around the world. Whether you need various screws with standard specifications or face special application challenges, our engineering team can provide professional support.

Hot Tags: radiator screws, China radiator screws manufacturers, suppliers, factory, Hex Socket Shoulder Screw, Low Profile Precision Shoulder Screws, shoulder screw, Slotted Shoulder Screw, Star Socket Shoulder Screw, Thumb Shoulder Screw