↵Hexagon socket screws

Hexagon socket screws are a type of screw with a hexagon socket drive mechanism. They are commonly used in machinery, precision instruments, molds, electronic equipment, and industrial assembly.

Product Description

Product Name: Hexagon socket screws

Material: Stainless steel

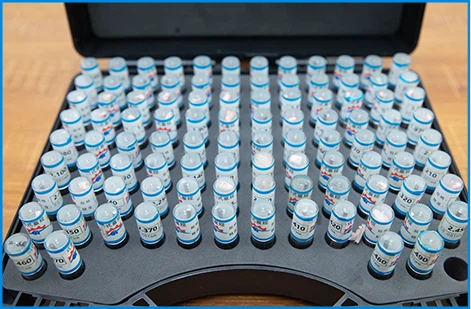

Thread diameter: 2.5mm, thread length: 4mm, pitch: 0.45mm

Drive type: Hexagonal wrench (hexagonal wrench/hexagonal wrench)

Manufacturer: Zeyao

Applications: Automotive, molds, machinery, electronics, and construction industries.

|

|

Common materials

1. Carbon steel

Grade: Grade 4.8 / 8.8 / 10.9 / 12.9

Application: General mechanical connections, high-load connectors

Heat treatment: Tempering, quenching + tempering (depending on the grade)

2. Stainless steel

A2-70 (304) is suitable for ordinary rust-proof environments

A4-80 (316) is suitable for strong acid and alkali, marine, medical and other corrosive environments

No need for electroplating, has natural corrosion resistance

3. Alloy steel (such as SCM435)

Used to manufacture 12.9 grade high-strength screws

Excellent mechanical properties and long fatigue life

Widely used in heavy-duty conditions such as automobiles, molds, and aviation

Surface treatment process

|

Surface Treatment |

Features |

Applicable Fields |

|

Black Oxide (Bluing) |

Oxidation resistant, slight rust protection |

General industry, internal machine parts |

|

Zinc Plating (White/Yellow) |

Low cost, decorative appearance |

Home appliances, furniture, hardware |

|

Dacromet |

Corrosion resistant, environmentally friendly |

Automotive chassis, construction machinery |

|

Nickel / Chrome Plating |

Shiny appearance, corrosion resistance |

Medical devices, decorative hardware |

|

Electroless Zinc Flake Coating |

Cr6+-free, high salt spray resistance |

Automotive fasteners, heavy industrial equipment |

Contact us to learn more about Hexagon socket screws or request custom options.

Contact Information:

Tel: +86 13380688971

WhatsApp: +86 13380688971

Email:sales@hky-hardware.com

Some Statistics About Us You Must Know

Choose the plan that suits you best.

18

+

YEARS OF EXPERIENCE

3000㎡+

FLOOR SPACE

160

+

MACHINERY EQUIPMENT

3500

+

SATISFIED CUSTOMERS

Production Process

As a fastener manufacturer with 19 years of experience, Zeyao boasts a comprehensive production system, ensuring consistent quality and on-time delivery for every fastener.

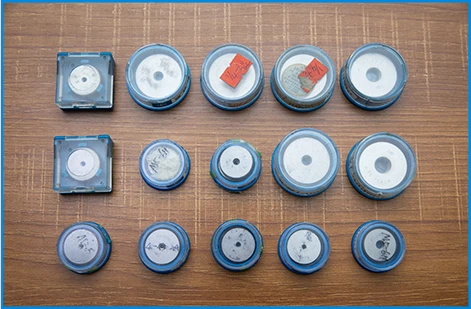

1. Raw Material

We purchase high-quality metal wire and strictly sort it into batches upon arrival, preparing it for subsequent processing.

2. Cold Heading

A cold heading machine processes the raw material into the basic shape of the fastener.

3. Thread Rolling

Next, threading, also known as threading, is performed to ensure the screw or bolt has a standard, clear profile.

4. Automatic Lathe Processing

Fully automatic lathes are used to further refine parts, including chamfering, turning, and slotting, to enhance dimensional accuracy.

5. Benchtop and CNC Lathe Finishing

For complex or customized fasteners, we use benchtop lathes and CNC machines for further processing to ensure they meet specific customer requirements.

6. Quality Inspection

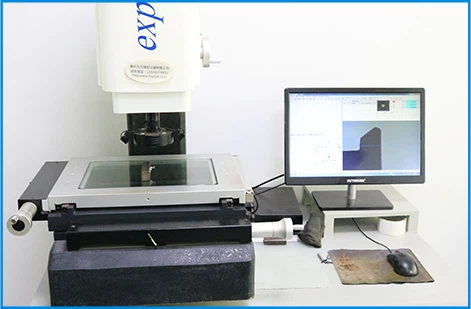

All products undergo rigorous manual and automated inspections to eliminate defective items and ensure that every shipment meets customer standards.

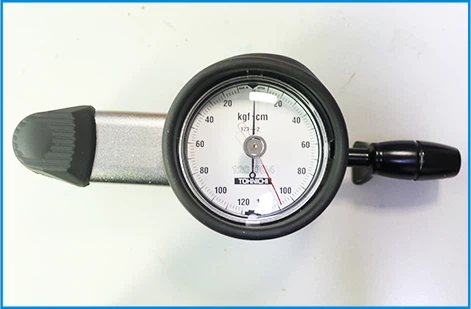

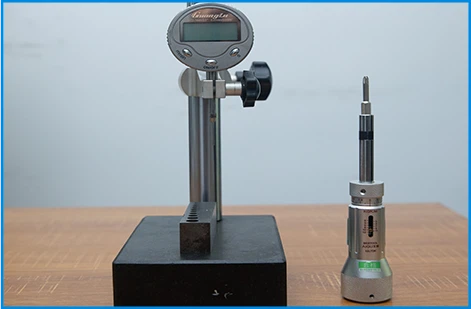

7. Functional Testing

Some products undergo specialized testing equipment to verify key indicators such as hardness, thread accuracy, and external dimensions.

8. Packaging and Shipping

Products are sorted, packaged, labeled, and boxed automatically or manually, and then neatly stacked in the warehouse for shipment.

Quality Control

Hot Tags: hexagon socket screws, China hexagon socket screws manufacturers, suppliers, factory, Cone Point Set Screw, Cup Point Set Screw, Extended Tip Set Screws, Oval Tip Set Screws, Soft Tip Nylon Tip Set Screw, Vented Cup Point Set Screws