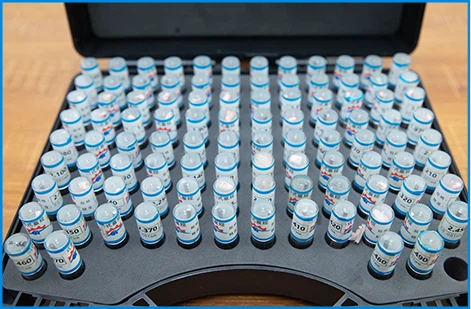

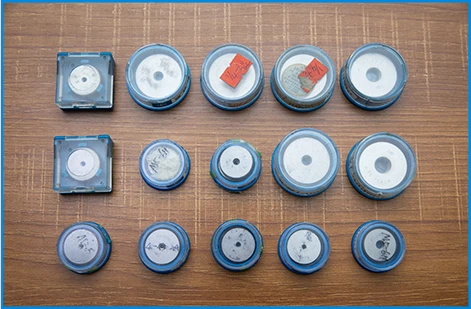

Product Picture

-Nose material:304 stainless steel,303 stainless steel, 410 stainless steel

-Body Material: 303 stainless steel

-Spring material:303 stainless steel

-Spring force: customized

-Diameter of the body:2mm-9mm

-Length:2mm-50mm

-Nose type:long nose

-Mount type:Press fit

-RoHS Compliance:RoHS 3 (2015/863/EU) Compliant

Micro Spring Plunger is a small-sized positioning component commonly used in mechanical assemblies, electronics, jigs, and fixtures. It provides precise positioning, indexing, and light pressure using an internal spring mechanism.

Key Features

Compact size – Ideal for tight spaces and precision equipment

Built-in spring – Ensures consistent pressure and reliable positioning

Easy installation – Threaded or press-fit designs available

Various tip materials – Available in steel, stainless steel, plastic, or nylon

Durable performance – Designed for high-cycle use and long service life

Production Process

As a fastener manufacturer with 19 years of experience, Zeyao boasts a comprehensive production system, ensuring consistent quality and on-time delivery for every fastener.

1. Raw Material

We purchase high-quality metal wire and strictly sort it into batches upon arrival, preparing it for subsequent processing.

2. Cold Heading

A cold heading machine processes the raw material into the basic shape of the fastener.

3. Thread Rolling

Next, threading, also known as threading, is performed to ensure the screw or bolt has a standard, clear profile.

4. Automatic Lathe Processing

Fully automatic lathes are used to further refine parts, including chamfering, turning, and slotting, to enhance dimensional accuracy.

5. Benchtop and CNC Lathe Finishing

For complex or customized fasteners, we use benchtop lathes and CNC machines for further processing to ensure they meet specific customer requirements.

6. Quality Inspection

All products undergo rigorous manual and automated inspections to eliminate defective items and ensure that every shipment meets customer standards.

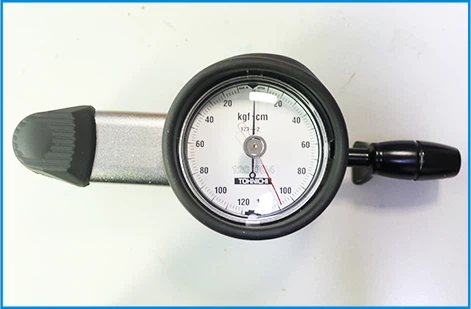

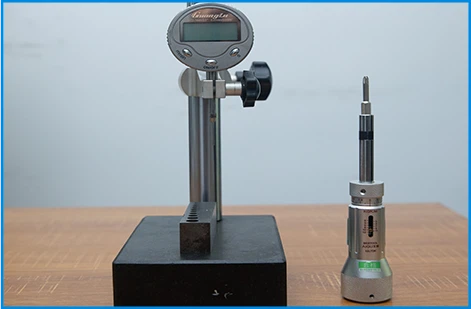

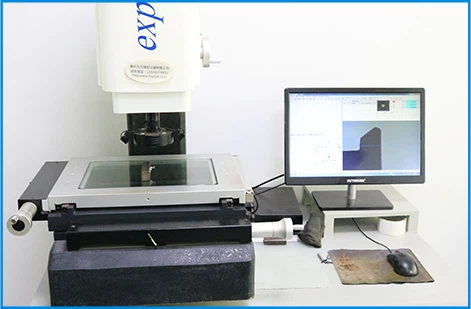

7. Functional Testing

Some products undergo specialized testing equipment to verify key indicators such as hardness, thread accuracy, and external dimensions.

8. Packaging and Shipping

Products are sorted, packaged, labeled, and boxed automatically or manually, and then neatly stacked in the warehouse for shipment.

Quality Control

Contact Us!

Contact us to request a sample and quote for our Micro Spring Plunger.

Contact Information:

Tel: +86 13380688971

WhatsApp: +86 13380688971

Email:sales@hky-hardware.com

Hot Tags: micro spring plunger, China micro spring plunger manufacturers, suppliers, factory, Ball Nose Threaded Spring Plunger, Flanged Threaded Spring Plunger, Locking Threaded Spring Plunger, other fasteners, Press Fit Spring Plunger, spring plunger