↵

Some Statistics About Us You Must Know

Choose the plan that suits you best.

18

+

YEARS OF EXPERIENCE

3000㎡+

FLOOR SPACE

160

+

MACHINERY EQUIPMENT

3500

+

SATISFIED CUSTOMERS

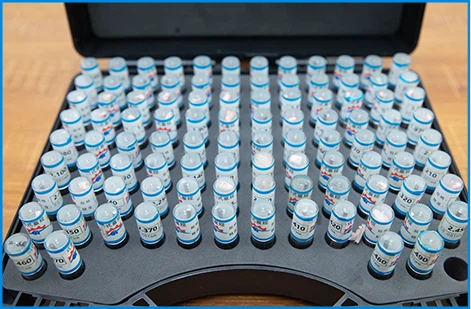

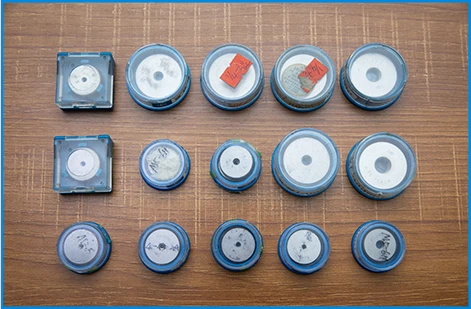

Product Picture

The threaded Sleeve Inserts utilize a hot-melt embedding process, melting the nut directly into the plastic substrate using specialized heating equipment. This process not only simplifies assembly but also creates unprecedented joint strength. The multi-hexagonal design ensures stable torque transmission, while the excellent thermal conductivity of copper ensures a more uniform and efficient hot melt process.

Customization is available

Sizes: Metric, Inch (UNC/UNF), and self-tapping threads.

Surface finishes: Galvanized, plain, nickel-plated, black, chrome, and painted.

Branding: Your logo or model number can be printed on the head for enhanced brand recognition.

Why Choose Us?

✔ Professional hardware fastener manufacturer with 19 years of export experience, ISO 9001 certified.

✔ 24-hour proofing service, sample delivery within 7-10 days, and mass production within 20-22 days.

✔ Free technical consultation to recommend the optimal material and structural design.

Production Process

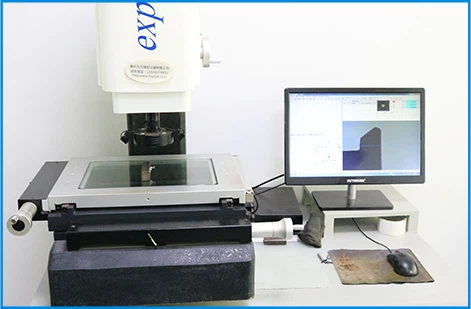

Quality Control

FAQ

Q1: Can you provide a custom threaded Sleeve Insert?

A1: It can be made according to the drawings and specifications provided by customers.

Q2: I want to keep our design secret. Can we sign an NDA?

A2: Sure, we will not display any customer's design or show it to other people; we can sign an NDA.

Q3: How do you guarantee quality?

A3: On the one hand, our company has a strong team and high-precision machines to guarantee quality; on the other hand, we have a strict production process from production to delivery.

Hot Tags: threaded sleeve insert, China threaded sleeve insert manufacturers, suppliers, factory, Brass Knurled Thumb Nut, Low Profile Ultra Thin Hex Panel Nut, other nuts, Slotted Round Nut, Square Nut, Tooth Lock Nut