↵

Some Statistics About Us You Must Know

Choose the plan that suits you best.

18

+

YEARS OF EXPERIENCE

3000㎡+

FLOOR SPACE

160

+

MACHINERY EQUIPMENT

3500

+

SATISFIED CUSTOMERS

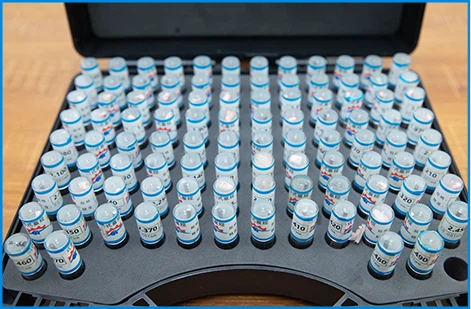

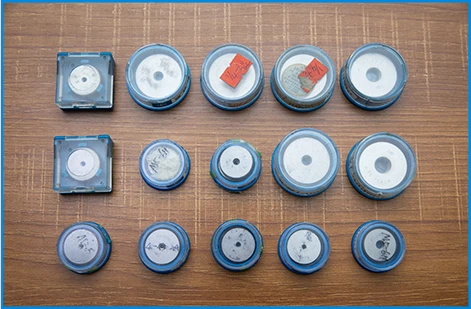

Product Picture

Zinc steel self-clinching nuts are fasteners used for joining thin plates or sheet metal. Their core feature is that embossed teeth and guide grooves interact to plastically deform the base metal under pressure, achieving single-sided locking.

Features

Single-Sided Installation: Installation is completed from only one side of the sheet metal, without penetrating the sheet metal or touching the back of the sheet metal. They are particularly suitable for closed or semi-closed profiles.

High Torque Resistance: The uniquely designed keyhole and pattern ensure a secure fit after compression riveting, effectively preventing the nut from rotating under torque. The locking structure formed by plastic deformation provides excellent rotation resistance.

Compact and Lightweight: Their compact size and light weight make them suitable for precision electronic equipment or space-constrained applications.

Material Compatibility: They can connect materials such as aluminum alloy and mild steel. However, please note that high-hardness materials such as stainless steel may affect the compression joint. Thread Specifications: Comprehensive coverage of Metric (M2, M2.5, M3, M4, M5, M6, M8, etc.), American Standard (#4-40, #6-32, #8-32, #10-32, etc.), and Imperial thread standards to meet the needs of diverse global markets.

Typical Applications

Chassis and Cabinets: Used for sheet metal connections to enhance structural strength.

Precision Electronic Equipment: Attaches components such as mobile phones and computer motherboards.

Automotive Bodies: Used for mounting interior components and assembly parts.

Aluminum Alloy Connections: Replaces welding, reducing the risk of deformation.

Note that the connection strength of Zinc steel self-clinching nuts is significantly affected by the strength of the parent material. Ensure that the parent material's hardness meets the required requirements during installation.

Production Process

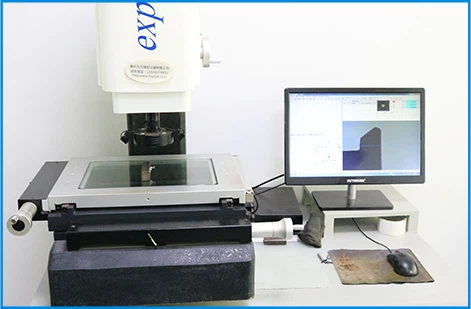

Quality Control

Custom Service

With 19 years of experience in the fastener industry, Zeyao Hardware specializes in manufacturing standard and custom fasteners, including screws, bolts, nuts, rivets, washers, CNC milling parts, and CNC turning parts. Whether you're choosing a standard product from our catalog or need a custom solution, we're here to help. We can ship standard fasteners right away if we have stock, and also offer custom manufacturing based on your specific drawings or samples. Contact us today for your custom requirements!

Hot Tags: zinc steel self-clinching nut, China zinc steel self-clinching nut manufacturers, suppliers, factory