↵

Company Product Scale

Choose the plan that suits you best.

18

+

YEARS OF EXPERIENCE

3000㎡+

FLOOR SPACE

160

+

MACHINERY EQUIPMENT

3500

+

SATISFIED CUSTOMERS

303 stainless steel blind hole flower tooth nut column is a specially designed fastener, mainly used in working environments where the bottom end needs to be closed, and has the function of sealing and waterproofing. This nut column is made of SUS303 stainless steel and is suitable for rust-proof working environments, such as aluminum plates, copper plates, etc. As a factory supplier specializing in the production of 303 stainless steel blind hole pressure rivet nut columns, we are committed to providing high-strength, corrosion-resistant thin plate fastening solutions for chassis cabinets, electronic equipment, aerospace, and other fields. The following is a description of our product's core advantages and technical details. We will refer to it as the nut column below.

Product introduction: Precise structural design to achieve reliable internal thread fixation of thin plates

Blind hole pressure rivet nut column is specially designed for thin plate connection scenarios with one side closed.

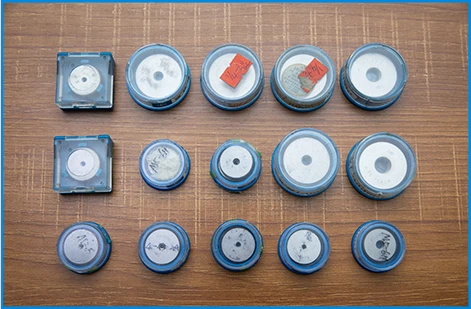

Product Picture

Product structure: one end hexagonal head + cylinder + back cutter groove + blind hole internal thread without through hole, pressed into the preset hole by a press, so that the plate is plastically deformed and embedded in the back cutter groove to form a permanent fixed internal thread.

Material: Made of JIS SUS 303 stainless steel, it has both corrosion resistance and excellent cutting performance without electroplating.

The applicable scenarios of the nut column include: sheet metal chassis, power distribution cabinets, PCB installation, aerospace equipment, and other thin plates with a thickness of ≥0.8mm, among which the hardness of the stainless steel plate must be ≤80RB.

Core features: anti-loosening and anti-vibration, high reusability, easy installation

Anti-loosening and anti-vibration design

The 30° bevel at the bottom of the thread tooth forms a wedge-shaped locking structure. When the bolt is tightened, the normal force forms an angle of 60° with the axis, and the anti-loosening performance is improved by more than 50%, especially suitable for vibration environments.

Production Process

Flower tooth embossing design: Increase the bite area with the plate, increase the shear resistance, and prevent rotation and loosening.

2. Long-term reliability and reuse

After more than 10 repeated disassembly and assembly tests, the locking force attenuation rate is less than 5%, and the service life is much better than that of ordinary nuts.

The blind hole structure avoids thread pressure loss and reduces maintenance costs by 30%.

3. Installation convenience

The back is completely flush, the surface is smooth, and it has no protrusions.

It is pressed in at one time by a riveting machine (no knocking), without welding or complex jigs.

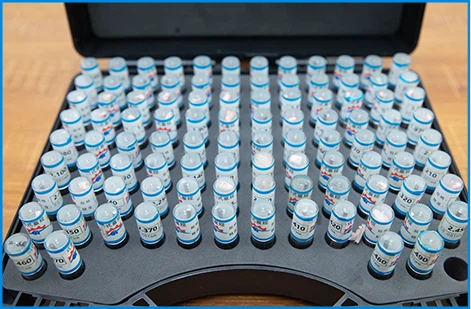

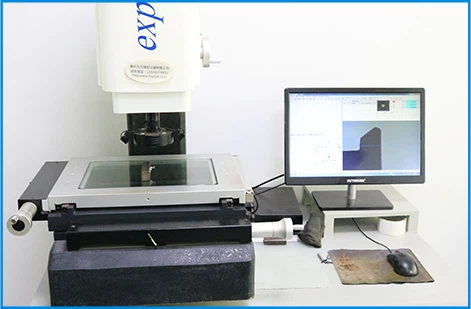

Quality Control

Product parameter specifications

Standard range: thread specification M2-M5, length 5-25MM, tensile strength ≥520 MPa

Special instructions: thread specification through hole type code SO, blind hole type code BSO; full thread below 10mm in length, hole expansion above 10mm; yield strength ≥196 MPa.

Customized service: design on demand, fast delivery

Size customization: non-standard length >30mm, outer diameter, and wall thickness

Tooth pattern customization: straight teeth (code "C" type), encrypted flower teeth (to improve the bite force of soft plates)

Material expansion: SUS 316L acid-resistant environment, SUM22 easy-to-cut carbon steel (galvanized surface)

Batch delivery: 15-day fast sample cycle, support million-level orders

Typical application scenarios

It is commonly used for chassis cabinet panel spacing assembly, which can simplify the installation process by 40%. It is also used for stainless steel PCB brackets and aviation equipment sheet metal. Because it has excellent corrosion resistance and can be maintenance-free, it can also be used for

thin-walled distribution boxes. It is suitable for plates with a thickness of 0.8 mm- 3 mm.

Hot Products

Quality assurance

Before delivery, the product will undergo 100% thread gauge detection + salt spray test ≥72 hours to eliminate quenching cracks, and the forging crack depth is ≤0.5 times the tooth height.

Why choose our 303 stainless steel blind hole pressure riveted nut column?

Because it can achieve permanent thread fixation of thin plates within a tolerance of 0.01mm, perfectly solving the three pain points of looseness in vibration scenarios, corrosion failure, and back bulge. If you have procurement and customization needs for 303 stainless steel blind hole flower tooth nut columns, please let us know and send us drawings and related requirements. We will give you a satisfactory product solution as soon as possible.

Hot Tags: nut colum, China nut colum manufacturers, suppliers, factory