The T-Head Bolt is a versatile and precision-designed fastener. Its unique T-head design allows for direct insertion into aluminum profile slots, facilitating quick and easy installation and ensuring structural stability. It is an indispensable component in industrial, automotive, railroad, and furniture manufacturing sectors.

Product Specifications

|

Item |

Technical Specifications |

|

Product Name |

T Head Bolt |

|

Material |

High-strength carbon steel, alloy steel, stainless steel (optional) |

|

Surface Treatment |

Hot-dip galvanizing, nickel plating, chrome plating, black oxide, coating/painting (customizable per customer requirements) |

|

Thread Type |

Metric threads (M4–M20), Imperial threads (1/4"–3/4") |

|

Bolt Length |

Customizable per customer request, common range: 20–150 mm |

|

T-Head Width |

Suitable for aluminum profile slot width 6–25 mm (customizable) |

|

Surface Friction Design |

Knurling, textured, or anti-slip treatment to prevent loosening |

|

Operating Temperature Range |

-40°C to 150°C (special materials can withstand higher temperatures) |

Specification

| Standard | ISO,JIS,GB,ANSI,BSW,DIN or non standard as customize |

| Material | 1.Stainless Steel:SS201,SS303,SS304,SS316,SS410,SS420 2.Steel:C45(K1045),C46(K1046),C20 3.Brass:C36000(C26800),C37700(HPb59),C38500(HPb58),c27200Cuzn37),C2800(CuZn40) 4.Bronze:C3604,C52100,H62,H65,etc 5.Iron:1213,12L14,1215 6.Aluminum Alloy:Al6061,Al6063,A7075,etc 7.Carbon steel:C1006,C1010,C1018,C1022,C1035K,C1045,C435#,40CrMo,42CrMo 8.Alloy steel:SCM435,10B21 9.According to customer demand |

| Grade | 4.8,6.8,8.8,10.9,12.9,etc |

| Size | M2-M24 or made to print as customer's specification |

| Specifications | Various shape size according to client's requirement |

| Thread | UNC,UNF,Metric thread |

| Finish | Plain,Zinc Plated(Clear/Blue/Yellow/Black),Ni-plated,black oxide,Sandblast and Anodized,H.D.G,DAC,GOEMET,as custom need |

| Package | Plastic bag + outer carton + pallets |

Product Picture

Product Features

T-Head Design

The head is T-shaped, allowing direct insertion into the aluminum profile slot without the need for an additional locator. During installation, the bolt automatically locks into the slot, improving installation efficiency and reducing manual operation difficulty.

Knurled or Textured Finish to Prevent Loosening

Knurled or textured heads increase friction, preventing the bolt from slipping or loosening under load, ensuring long-term structural stability and reliability.

High-Strength Material, High Load-Bearing Capacity

Made of high-strength carbon steel, capable of withstanding high tensile and shear loads, suitable for heavy-duty applications. Heat treatment ensures a balance of toughness and hardness, guaranteeing no deformation under high-intensity applications.

Excellent Corrosion Resistance

Bolts can be galvanized, nickel-plated, chrome-plated, or black anodized, preventing rusting during long-term use in humid or mildly chemical environments. Suitable for outdoor, marine, chemical, or humid environments.

Multiple Customization Options

Bolts support various thread types, head sizes, and lengths, providing customized solutions based on customer aluminum profile slot specifications, load requirements, and operating environment.

Production Process

As a fastener manufacturer with 19 years of experience, Zeyao boasts a comprehensive production system, ensuring consistent quality and on-time delivery for every fastener.

1. Raw Material

We purchase high-quality metal wire and strictly sort it into batches upon arrival, preparing it for subsequent processing.

2. Cold Heading

A cold heading machine processes the raw material into the basic shape of the fastener.

3. Thread Rolling

Next, threading, also known as threading, is performed to ensure the screw or bolt has a standard, clear profile.

4. Automatic Lathe Processing

Fully automatic lathes are used to further refine parts, including chamfering, turning, and slotting, to enhance dimensional accuracy.

5. Benchtop and CNC Lathe Finishing

For complex or customized fasteners, we use benchtop lathes and CNC machines for further processing to ensure they meet specific customer requirements.

6. Quality Inspection

All products undergo rigorous manual and automated inspections to eliminate defective items and ensure that every shipment meets customer standards.

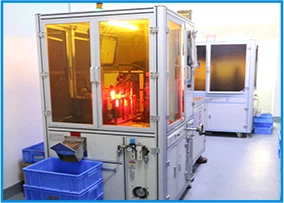

7. Functional Testing

Some products undergo specialized testing equipment to verify key indicators such as hardness, thread accuracy, and external dimensions.

8. Packaging and Shipping

Products are sorted, packaged, labeled, and boxed automatically or manually, and then neatly stacked in the warehouse for shipment.

Hot Tags: t head bolt, China t head bolt manufacturers, suppliers, factory, Wing Head Thumb Bolt, T Head Bolt, T Slot Bolts, Hex Socket Head Shoulder Bolt, 5 16 18 Carriage Bolt without Square Neck, other bolts